Mining Wear Parts for the Toughest Conditions

Domite® (also known as Laminite®) is CR Powered by Epiroc’s maximum abrasion-resistant block and wear product for mines.

Protect your equipment and keep machines running with mining wear products that last longer with less maintenance.

BY THE NUMBERS

100

Of shapes and sizes available

700

Brinell nominal hardness

6

Times longer wear life*

*Compared to conventional wear liners.

What is Domite?

Domite (also known as Laminite) combines Cr-Mo white iron, metallurgically bonded in a vacuum furnace. This bonding process gives it extreme abrasion resistance, with a Brinell Hardness of 700-750.

Our mining wear parts are suitable to replace conventional wear plates (Q&T), as well as NiHard and Overlay.

Some of the wear products we make include:

- Chocky bars

- Chocky blocks

- Domite wear bars

- Domite wear blocks

- Grizzly bars, decks, and fingers

- Skid bars

- Wear buttons

- Wear liners

- And other wear protection

Mining Wear Parts

Right for Your Application

Domite wear parts are available in various shapes, sizes, and thicknesses for any application, including bucket components.

Dramatically Tough

With a hardness of 700 Brinell (63Rc), our wear material is ready to stand up to anything you can throw at it.

Customizable Wear Products

Domite can be cut, studded, and chamfered to customize the protection on your machine or equipment. We can design custom parts from our standard range, to meet your requirements.

Designed to Outlast the Competition

Our block and wear parts are engineered to be long-lasting and durable, no matter the conditions. Long wear life reduces time spent on maintenance and change out, increasing plant and machine up time, so you can exceed your productivity goals.

When maintenance is required, the parts are optimized for fast change outs. Domite wear parts can be welded easily and quickly so your machines can get back to work faster.

Extensive Range of Wear Parts

We supply a wide range of mining wear products in Australia and worldwide, including bucket protection, wear liners for chutes and chocky bars for patch work on mobile and fixed plant machines.

Chocky bars and wear buttons: designed for patch work on excavators, dozers, shovels, and draglines. The notched design means they can be curved around a surface before welding.

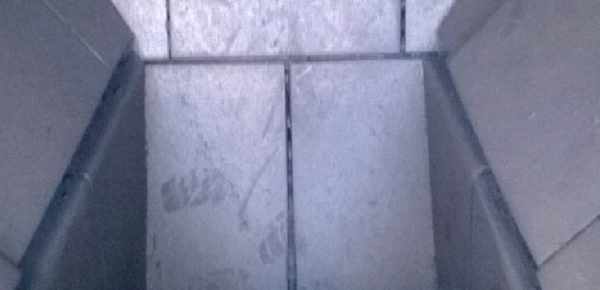

Wear liners, bars, and billets: designed for chutes, hoppers, and bins in processing facilities. With six times the life of convention wear material, you’ll spend less on maintenance and change outs.

Microledges: designed for chutes and hoppers, preserving chute integrity and taking all impact.

Skid bars: designed for buckets and truck trays. Unrivaled wear protection package to keep the bucket and truck tray structures protected.

Rockbox liners: designed for areas at risk of premature failure in processing facilities and crushing, producing a ‘dead box’ effect. Save by replacing worn sections, not the entire wear liner.

Resources

Explore Case Studies

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.